Industry 4.0, Eurostampa unveils the complete integration between printing machines and ERP

EUROSTAMPA stands out as a pioneer of Industry 4.0, having developed an integrated system between OMET machines and their ERP for improving production management. The software, developed by the electronic R&D departments of OMET and EUROSTAMPA, make all the process parameters flow directly into the company’s ERP, with a completely customized interface.

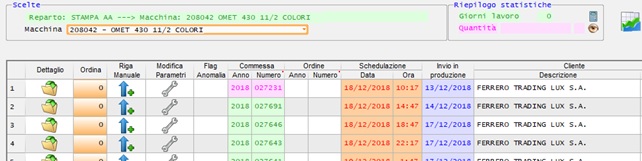

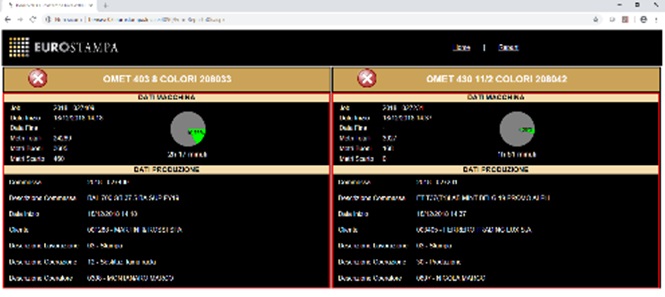

The Transparent Factory Cloud software, installed on each OMET printing line, displays in real time the working conditions and the process parameters of the machine. These data flows directly to the company server that creates CSV files to be downloaded and processed at any time.

Eurostampa, located in Bene Vagienna (Cuneo), is an industrial giant of prestigious labels, OMET’s customer for a long time. The company has asked OMET to develop a software able to make all data of their production lines flowing directly into their ERP. This direct transmission would bring big advantages in terms of speed and effectiveness of production management.

Developing this new solution for Eurostampa was an interesting challenge and a big opportunity for OMET. Beyond putting in direct connection the machine and the ERP, our R&D Electronic Department customized the reading interface and some parameters according to the customer’s needs instead of following the standard protocols. Any OMET customer could have the possibility to customize the monitoring of the processes, having access to readily available information and thus managing the production more efficiently.

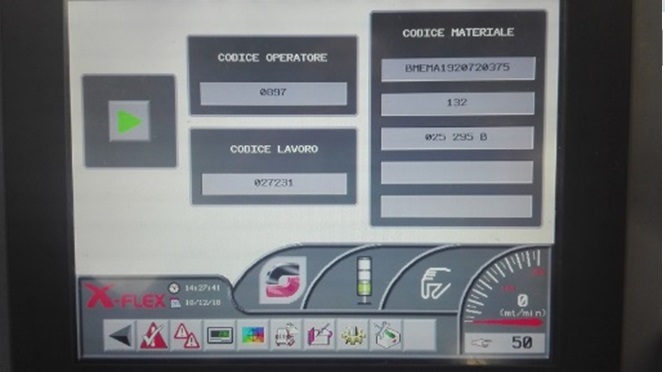

To achieve this goal, the PLC software and the operator panel were customized, and the router was improved with some scripts that allow the ERP to poll the machine and check the information needed (i.e. with cyclic calls every 30 seconds). Everything works with http and text answers.

This “customized” innovation, replicable on any OMET machine, demonstrates once again OMET’s attention to customers’ needs and willingness to develop together with them innovative technologies aimed at increasing their competitiveness.

Andrea Bergadano, Eurostampa Project Manager, express his full satisfaction with the work carried out with OMET: “Eurostampa S.p.A. continues to invest in new technologies, whether they concern printing or support production. Industry 4.0 gave us the opportunity to invest simultaneously in both directions. The purchase of latest-generation OMET machines and their integration with our ERP system was the result of the respect and collaboration between the two companies. Working in close synergy, we reached our goal: to read and represent the printing process in real time, improving programming and production forecasts”.

“The purchasing department can better organize the supply of raw materials – adds Bergadano – improving their availability and timing. Furthermore, the possibility of passing start-up data directly to the machine simplifies and speed up the information transfer”.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group