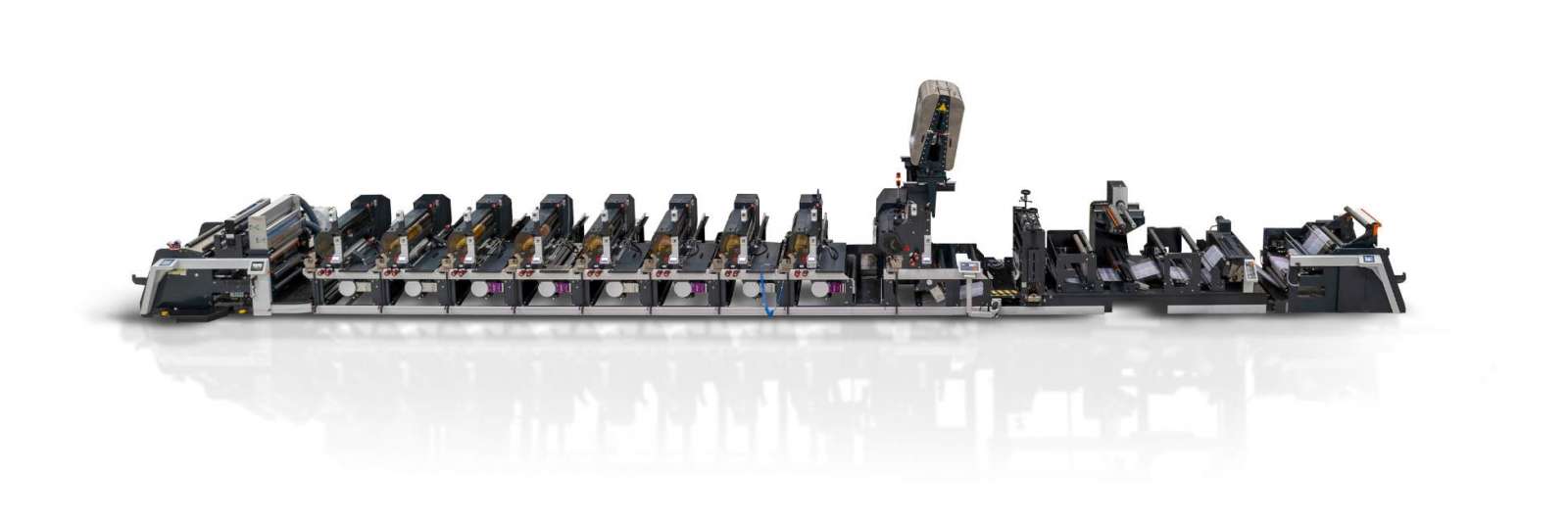

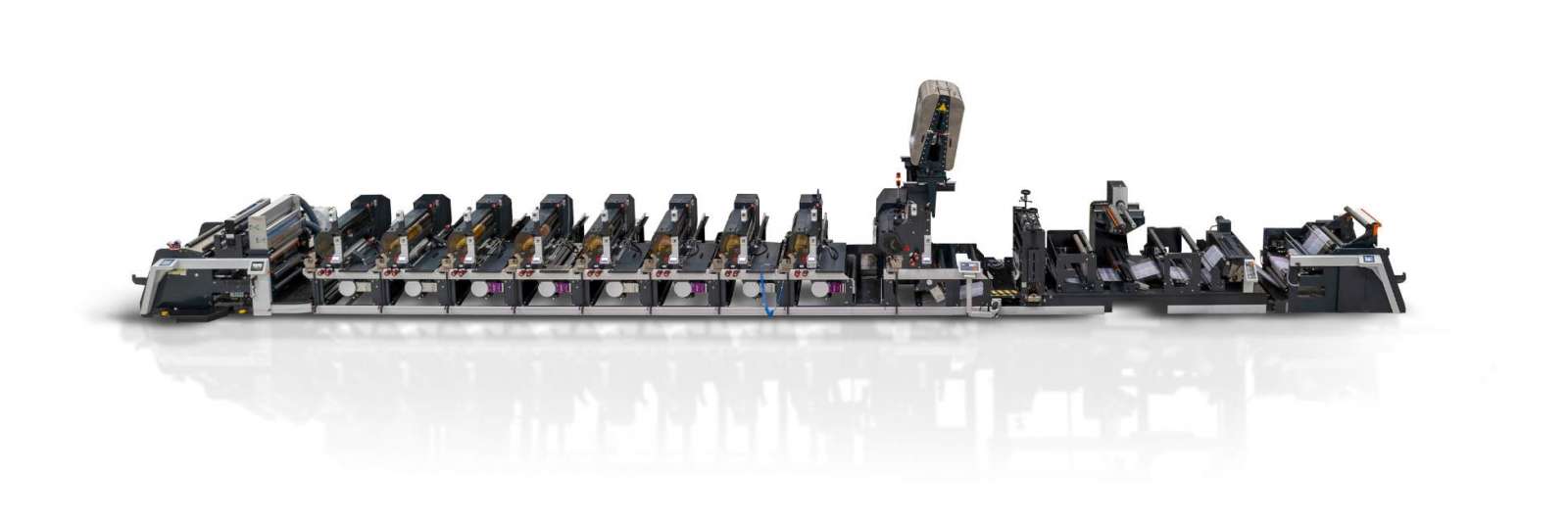

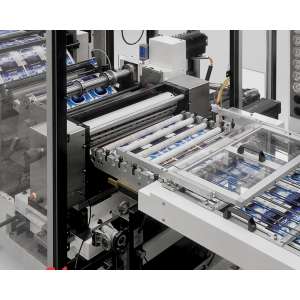

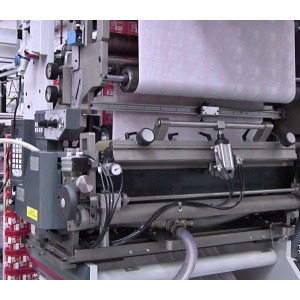

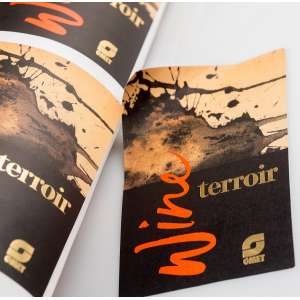

Varyflex V2 is a narrow and mid-web flexible packaging printing machine with a unique platform concept designed to combine a wide set of printing and finishing technologies. UV, water base or solvent base flexo printing, movable gravure, screen and offset printing can be easily combined with many finishing options like hot or cold foil processes. OMET Varyflex V2 packaging press offers servo-driven flexible printing modules and

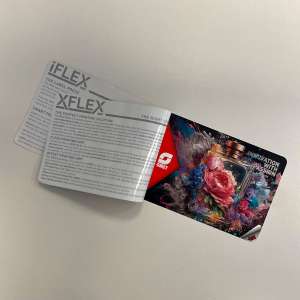

can be specifically designed to fit the needs of in-line folding carton converters producing for the food, tobacco, consumer packaged goods and cosmetic market sectors. OMET Varyflex V2 breaks the limits and jumps into a unique area of quality, short runs and profitability for the printing of flexible packaging, folding carton, single or multi layer films, laminates, boxes, lottery tickets, security labels, aluminum blisters for the pharmaceutical sector and other special applications.

Varyflex V2 modular design allows to combined and implement in-line, with no limitations, different printing technologies, as well as special finishing applications and converting units, to always get to the final product in one single passage.

- Hot Foil, Cold Foil, in-line Lamination, web turn bar, print on adhesive can slide on rail for easy positioning anywhere along the press. The press is reconfigured within seconds!

- Different converting solutions with exclusive die-cutting systems by OMET

- Different typologies of slitting systems can be integrated in-line into the converting section.

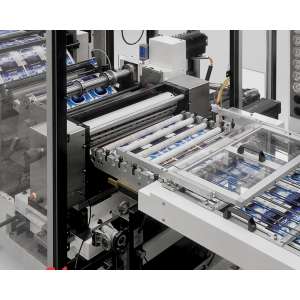

- 3 main delivery options: Roll-to-Roll, Roll-to-Blank, Roll-to-Sheet.

- Interchangeable units for UV, water-based and solvent-based flexo printing, rotary silk-screen, rotogravure, cold and hot foil. The press is reconfigured within seconds!

- Single and double rewinder for film and self-adhesive

- No-stop unwinder and rewinder

- Carton equipment package for folding carton printing

- Auto decurler for thick carton

- Stackers for small format sheets

- Shingling table for finished blanks

- High-pile stackers for off-line finishing

- Simple and intuitive HMI interface

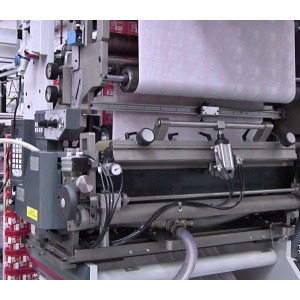

- MD pre-register, auto register and re-register functions to reduce waste and increase job versatility

- Multivision system for a fully automatic MD and CD print registration

- Automatic register control system - Mark-to-Cylinder

- Transparent Factory is OMET remote diagnostic service for press performances monitoring and software upgrades via internet

- Easy setting and storing of job parameters - web tension, print repeat, anilox volumes, color sequence, production statistics

- Job recipes fully uploaded remotely from pre-press room

- Ergonomic design to reduce the operator’s stress and increase control

| 430 | 530 | 670 | 850 | | Max speed | up to 250 m/min (820 fpm)( | up to 250 m/min (820 fpm)( | up to 250 m/min (820 fpm)( | up to 250 m/min (820 fpm)( |

| Unwinding reel diameter | 1000 - 1500 mm (40’’- 60”) | 1000 - 1500 mm (40’’- 60”) | 1000 - 1500 mm (40’’- 60”) | 1500 mm (60”) |

| Web width | 430 mm (16 7/8'') | 530 mm (20 7/8'') | 670 mm (26 3/8") | 850 mm (33 4/8'') |

| Print width | 420 mm (16 4/8'') | 520 mm (20 4/8'') | 660 mm (26'') | 840 mm (33 1/8'') |

| AVAILABLE PRINTING TECHNOLOGIES | | | | |

| Flexo UV/UV LED | 11' '4/8 - 33'' | 11'' 4/8 - 33'' | 11'' 4/8 - 33'' | 14'' - 33'' |

| Solvent-base Flexo | 11''4/8 - 33'' | 11''4/8 - 33'' | 11''4/8 - 33'' | 14'' - 33'' |

| Flexo Water Base | 11''4/8 - 33'' | 11''4/8 - 33'' | 11''4/8 - 33'' | 14'' - 33'' |

| Rotary silk-screen | 12''- 25'' | 12''- 25'' | 16''- 33'' | 16''- 33'' |

| Rotogravure | 12''- 26'' | 15’’- 26’’ | 15''- 26'' | 17''- 26'' |

| Offset (Sleeve) | | | 16''- 32'' | 16''- 32'' |

| CONVERTING | | | | |

| Label die-cutting section | 12"-24'' | 16"-24" | 22"-32" | |

| Cardboard die-cutting station | 18''- 32'' | 20''- 32'' | 24''- 32'' | |

| “Flying Cut” | 6''- 33'' | 6''- 33'' | 6''- 33'' | 6"-33" |

| OTHER TECHNICAL INFORMATION | | | | |

| Rewinders diameter | 760 mm (30'') - 1000 mm (40") - 1500 mm (60") | 760 mm (30'') - 1000 mm (40") - 1500 mm (60") | 760 mm (30'') - 1000 mm (40") - 1500 mm (60") | 760 mm (30'') - 1000 mm (40") - 1500 mm (60") |

The technical data contained in this table are not binding. OMET is entitled to change the features of the products without prior notice.

Flexo

Printing

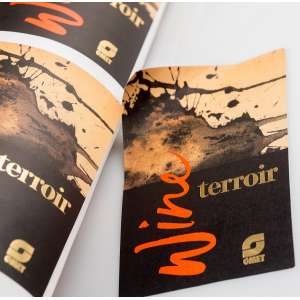

Offset by Sleeve

Printing

Rotary silkscreen

Printing

Rotogravure

Printing

Hot Melt

Finishing

Cold Seal

Finishing

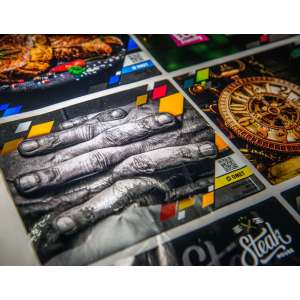

Cold Foil

Finishing

Hot Foil

Finishing

In-line lamination

Finishing

Peel & Seal

Finishing

Delam/Relam - Glue-side printing

Finishing

Die-cutting / Embossing cassette

Converting

Rock'n'Roll Dual Function

Converting

Fly Cutting system

Converting

UV & UV LED

Drying & Curing

Hot Air drying systems

Drying & Curing

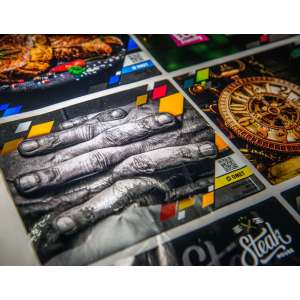

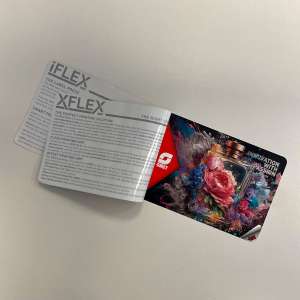

Self-adhesive labels

In-Mold Lables (IML)

Flexible packaging

Shrink sleeves

Aluminum packaging

Folding carton

Special applications

Booklet and coupon labels

Wrap Around Labels

Wet-glue labels

Tube laminates