PRINTING THE BEST QUALITY EVER

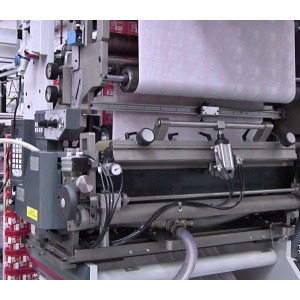

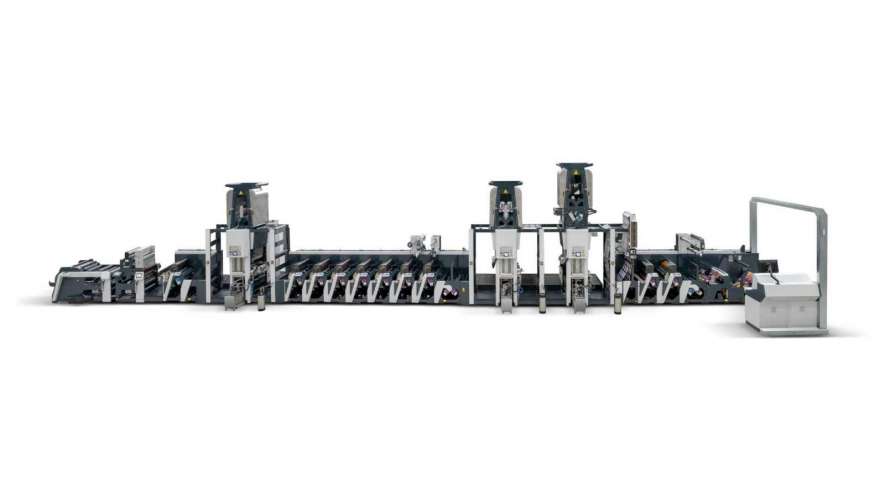

XFlex X7 has been created with the target to merge the best features of XFlex X6.0 and Varyflex V2 into a new amazing printing press. It’s a 670mm (26”) mid web printing machine ideal for flexible packaging and shrink label printing at the maximum level of quality, thanks to the unmatched technology of XFlex flexo unit, motorized printing pressure and Multivision camera on each printing unit with On-the-Fly pre-registration.

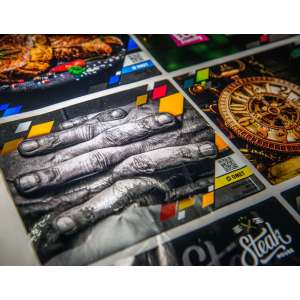

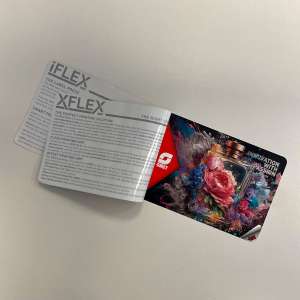

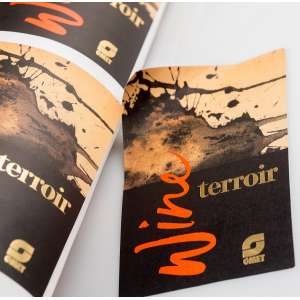

XFlex X7 offers different possibilities of combination printing and special effects for high-value final products as like the brand Soft Touch Rotogravure unit allow ing new and unmatchable results, the Soft Touch Vertical Flexo with longer drying tunnel and Rotary Screen 670mm width.

The integration of digital Servo Drives enables very accurate set-up operations and automatic On-the-Fly pre-registration of the plates to get them in position simply by pressing a button, with no waste of time and material. The automatic positioning of the plate at simple passage of the mark allows an automatic registration, independent of the web path and of the operator.

Automatic printing registration adjustment and control based on a multiple camera scanning system. It can control both machine and cross side of each single printing unit, simultaneously and concurrently, and get the machine ready to print in less than 1 minute generating nearly no waste.

The X7 guarantees an intelligent printing process with the automatic positioning of the printing pressures at every change of speed, substrate thickness and repeat length thanks to ultra precise motorized pressure setting of both the anilox roll and the impression cylinder. The “No Panic” function gives the possibility to automatically reset the pressures and return to the initial settings by pushing a simple button.

The X7 modular design allows to combined and implement in-line, with no limitations, different printing technologies, as well as special finishing applications and converting units, to always get to the final product in one single passage.

| XFLEX X7 | |

| Web width | 680 mm |

| Print width | 670 mm |

| Max speed | up to 250 m/min (820 fpm)( |

| Unwinder (diameter) | 1000 mm + 760 mm |

| Rewinder (diameter) | 760 mm + 1000 mm |

| Printing transmission | Independent direct-drive motors |

| Printing Technology | Sleeves |

| Machine and cross register adjustment | Automatic |

| Automatic register control | Automatic |

| AVAILABLE PRINTING TECHNOLOGIES | |

| Flexo UV - WB - SB | 12" - 25" |

| Vertical Flexo | 12" - 25" |

| Rotary silk-screen | 16" - 25" |

| Rotogravure | 16" - 26" |

| AVAILABLE DIE-CUTTING SYSTEMS | |

| Cassette-style die-cutting station | 16'' - 25'' |

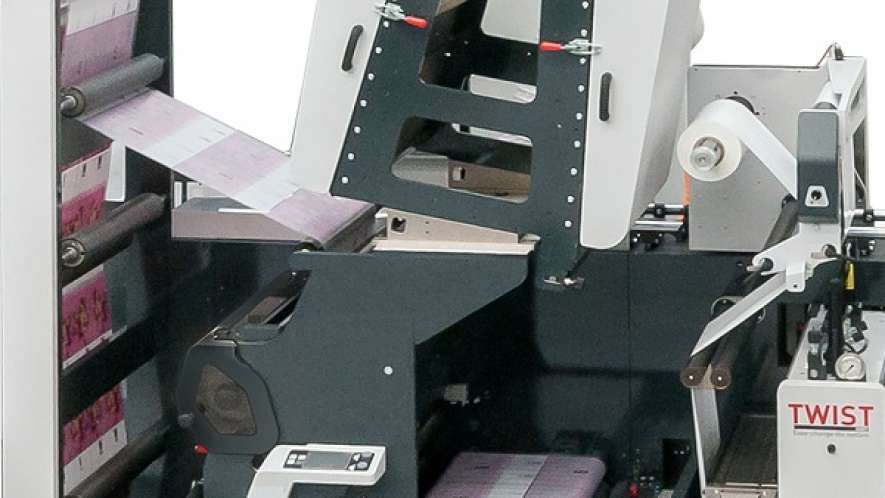

| TWIST die-cutting station | 16'' - 25'' |