Coreti (Spain) aims high investing in OMET machines

Three OMET lines installed in one year. Coreti, Spanish company based in La Coruña considered among the best printers in the Iberian region, is really enthusiastic of OMET technology, which was able to meet their necessities through different solutions.

Coreti was founded in 1991 by the general manager Luis Fernández Vilela and was grown in the world of graphic arts. Now it is a company dedicated to the production of adhesive labels and can count on more than 25 years of history and experience in this sector. The company went through a big growth and expansion in the last few years. This brought Coreti among the top-ten label printers of Spain. This result was achieved thanks to the effort, the tenancy and the hard work of the management, but also to the precious contribution of the skilled team of operators.

Currently, Coreti has more or less 110 workers. Celso González, Coreti CEO stated: “Together we are a ‘big family’. Our team is wide, involved in the company, with a big experience in the sector and with the desire to learn, train and renovate all the time”.

Coreti has a single location in Poligono de Bergondo, in La Coruña. The building was recently renewed and inaugurated. It is located on a surface of more than 7000 m2 and counts on 4500 m2 of built area with 1000 m2 dedicated to offices on three floors.

“This larger infrastructure allowed us to expand our production capacity and to support Coreti’s expansion and growth in the last few years – explains González -. We can rely on a wide commercial network that includes Spanish territory as well as a part of Portugal, even if our labels go much farther. We have started to export our labels to other countries, but we are already present in every country thanks to the growth and the expansion of our customers. As we grow with them, our labels always accompany their product everywhere”.

Coreti produces labels for different sectors, especially for wine, beer, oil bottles or gourmet products, as well as in industrial activities such as food, logistics or distribution and others. “We print our labels using all the printing technologies existing on the market – says González -. We have digital, offset, flexographic and silk-screen printing press. Furthermore, we try to constantly innovate the materials and the finishing, in order to make our labels stand out on the market”.

Coreti’s CEO says that “technologies at our disposal allow us to offer a wide range of solutions to our current and potential clients, including silk-screen, glitter, hot stamping, varnishing, embossing, special die-cuts, variable data or backside printing, booklet labels, and others. Thanks to our constant commitment, Coreti has become the reference in the production of labels for wine, beer and oil sectors, in which we grow in volume, year after year. For this reason, we try keep up with all the innovations and attend all the events related to them”.

“We believe that our strength is the constant commitment that we dedicate to satisfy the customer in all his orders. We put quality, constancy and good service. In fact, we consider that all our values benefit both our clients and ourselves” says González. “We inform, suggest and help solving problems, because we are not only label producer. We try to get to know our customers and their products, in order to help them with the best dedicated suggestions”.

The collaboration with OMET

“The cooperation with OMET started at the beginning of 2017 – says González – with the installation of one OMET XFlex X5 with ten colors. A new model dedicated to the production of label but also prepared to print on flexible packaging and on folding carton up to 250 g. In addition to this purchase, we bought two other presses from OMET, another XFLEX X5 with six colors and a 4-color IFLEX, the latest of our machine range”.

“OMET press stands out for robustness and precision, as well as for flexibility that allows personalizing its configuration according to the user’s necessities – adds González -. The XFlex X5 is an ergonomic printing system that does not require any direct intervention of the operator, thanks to the Vision 1 system for automatic register adjustment and control. You can work with different materials and, both rigid and flexibles, maintaining a basic configuration. It also permits to use both UV ink and water-based ink, if the press is equipped with a combined drying system with hot air and UV cassettes. This press integrates a chill drum on every print unit, which prevents the heat from affecting the substrate, a crucial detail if you work with films or plastic materials.

The in-line integration of silkscreen printing unit, cold Foil, web turn bars, print on adhesive significantly reduce waste levels, time of set-up and run-to-register. With OMET presses we can make peel and seal jobs quickly and easily and they gave us the opportunity to integrate silk-screen printing technology, being able to produce labels that require up to 10 colors, one of which printed with silk-screen unit. The service has always provided fast and clear support to the few problems we have had until now”.

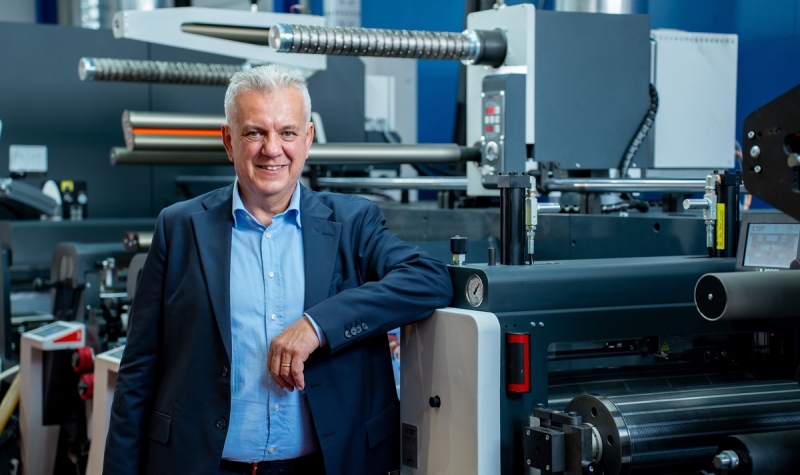

Photo: from the left Mr. Luis Vilela (President of CORETI), Mr. Enric Pont (OMET agent for Spain and Portugal) and Mr. Celso González (ejecutive and product manager of CORETI).

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group