Smart Labels and future technologies

OMET invests in the future of labels: Ribes Tech is an OMET Group startup focused on the development of innovative printed electronics technologies for home automation, smart cities and IoT applications. Smart labels are the new frontier of printing: intelligent labels that can interact with the surrounding environment.

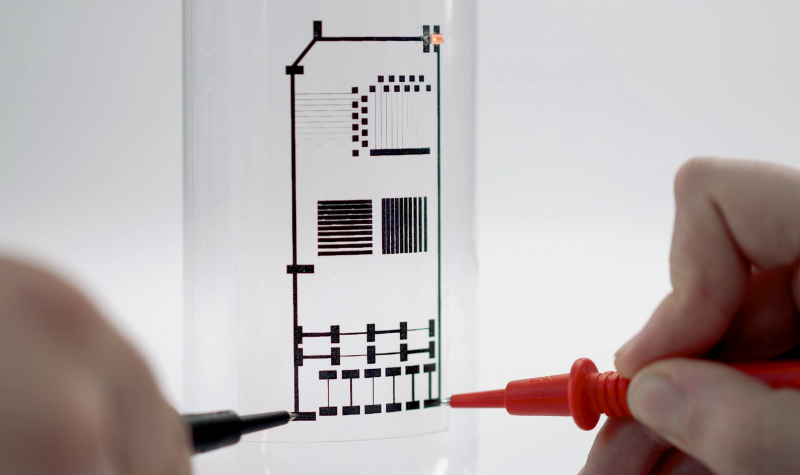

Ribes Tech is a deep-tech company born from a collaboration project between OMET and the Italian Institute of Technology in Milan, to develop and bring to the market novel printed electronics technologies, thanks to the experience and skills of OMET in the world of printing. Ribes Tech is specialized in the production of roll-to-roll photovoltaic modules printed using special inks on flexible and lightweight plastic films, which can be used as an energy source to power low-consumption indoor electronics for home automation, smart cities and especially Internet of Things applications.

But Ribes Tech’s research activities are also expanding into other fields: in particular, in recent times, great interest has been developing around the world of smart labels, functional labels that interact with the surrounding environment thanks to the integration of electronic components and sensors.

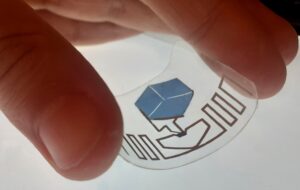

A renowned example that has nowadays become a commodity is represented by labels with antennas and RFID chips, which, however, constitute a typically passive technology as the product does not have power sources integrated: the label communicates only when a telephone is approached to read it or in proximity of an antenna. The simple manufacturing methods and mechanical characteristics of Ribes Tech’s photovoltaic modules could allow to power these labels independently and make them active; this without changing their mechanical properties and with a limited impact on the production chain, because the ability to print the photovoltaic module makes it easy to integrate it into the current production processes. It is therefore clear that Ribes Tech’s technology can pave the way to the implementation of novel wireless applications not approachable with batteries or standard silicon photovoltaic modules.

A renowned example that has nowadays become a commodity is represented by labels with antennas and RFID chips, which, however, constitute a typically passive technology as the product does not have power sources integrated: the label communicates only when a telephone is approached to read it or in proximity of an antenna. The simple manufacturing methods and mechanical characteristics of Ribes Tech’s photovoltaic modules could allow to power these labels independently and make them active; this without changing their mechanical properties and with a limited impact on the production chain, because the ability to print the photovoltaic module makes it easy to integrate it into the current production processes. It is therefore clear that Ribes Tech’s technology can pave the way to the implementation of novel wireless applications not approachable with batteries or standard silicon photovoltaic modules.

Such a relative simplicity of integration would pair with a high added value for the label, which in illuminated environments (even with artificial light and low intensities) could communicate independently to any compatible device and log data from sensors integrated into the small RFID chips. This greatly increases the amount of data that the label can collect and transmit to the end user. A further evolution contemplates that the antenna for wireless communication can also be printed in the same printing step as the photovoltaic cell, thus further reducing costs and simplifying the label manufacturing process.

RFID smart labels have applications in particular in logistics, warehouse management and retail, to increase productivity while reducing waste and missed sales opportunities. On the other hand, the need for increased functionalities on the consumer side could be satisfied by a further evolution of smart labels, represented by the so-called “dynamic labels”, fully printed. These were discussed in the fifteenth episode of OMET TV: in this case the photovoltaic cell powers a simple display, also printed with electronically active inks, which modifies the message shown as a result of interactions with the surrounding environment or of logic functions integrated into the label itself. The end user will be able to take advantage of a new digital experience integrated into traditionally static products, to which new aesthetic and practical features are added, granting an unprecedented degree of interaction with the product.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group