New goal: extreme quality

New products, new technologies and new ways of working to guarantee extreme quality and precision on any line: Marco Calcagni, OMET Sales & Marketing Director, introduces the year 2020 revealing the path taken by OMET to lead an increasingly complex and ever-changing market.

The label and packaging market is changing rapidly. There is an increasing need for efficiency, speed, automation and, above all, quality. OMET research and development is following one of the main market trends, definitely pursuing the extreme quality of printing, in particularly for the flexographic technology. In this field, the latest technological innovations introduced by OMET are leading to the complete elimination of the “bouncing” effect, typical of the flexographic printing, thanks to new and patented systems that ensure the stability of printing quality over time.

New orientations are getting ahead in the market, first of all the trend towards savings of energy and materials such as inks and paper. Thanks to the new production technologies and to the pressure adjustment of the rolls involved in the printing process – anilox and cliché – the inks dosage becomes more and more precise, defining the exact quantity needed to obtain the goal without any waste. Regarding the stability of the register, the goal of zero waste in job change is getting closer.

To guarantee this extreme level of quality and precision for each press, OMET has advanced all the printing technologies – flexo, rotogravure, offset and digital – offering the possibility of integration on any available platform. This way, OMET can configure completely customized machines, allowing customers to have the highest efficiency and the best qualitative results for any kind of job they have to carry out.

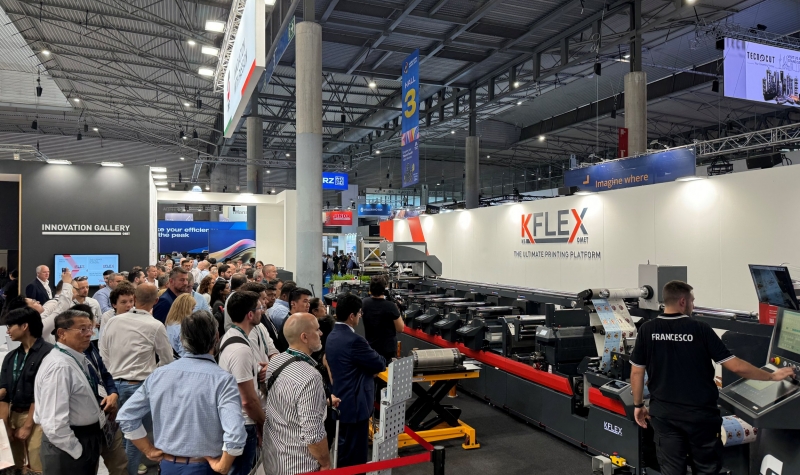

The new OMET X7 presented at Labelexpo Europe 2019 has been designed according to these goals and is a revolution for the printing world. It will be available in a 670 mm version to optimize the production of the medium-volume products in strong evolution, such as shrink sleeve labels. We turned the spotlight also on the new hybrid OMET XJet, which today is the only machine with combined printing able to guarantee excellent results and very high performances up to 80 meters per minute on all types of support, including shrink labels. The XFlex X6 combination with the TAU RSC digital inkjet unit is certainly the most advanced solution available on the whole label market.

OMET has invested on several fronts, paying great attention to the ease of use of the machines, always designed to ensure a constant product quality. Today the operator is only asked to remotely control the production process, without manual intervention, allowing greater production control and higher safety at work.

Customer service – both before and after sales – is another function on which OMET is strongly investing. The rapid evolution of the market generates the need to maintain a constant contact between technology producers like OMET and customers, during the investment analysis and the following phases. Thanks to the flexibility of our machines, it is possible to invest in their evolution even at a later stage, making customized changes and upgrades that make them always up to date with the needs of the customers.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group