Labelexpo 2017: OMET revolution continues

From 25 to 28 September, OMET will be among the main exhibitors at Labelexpo Europe 2017 in Bruxelles. The appointment will be at the booth C49-C53 , hall 6, the usual point of reference for technology and innovation: all the visitors will attend an extraordinary show, with amazing live demos showing all the potentialities of OMET machines, always one step ahead of competitions.

For many years, Labelexpo has been the main occasion for OMET to reveal his concept of innovation in the label and flexible packaging printing market. In 1995 OMET Multiflex was the first machine to show a real quick-job changeover thanks to the exclusive removable inking cassette, with astonishing printing quality result, giving a boost to flexo printing potentiality.

Many players of this sector still think of the Varyflex launched in 2001 as the best innovation ever seen in Labelexpo: it was the first machine with servo gearless flexo technology in the narrow-web printing market. Such innovative solution guaranteed a perfect printing registration and a consistent reduction of waste, which means high quality products and costs saving. In combination with the first electronic control, it has become in the following years a sort of benchmark for all machine manufacturers. It was a sort of revolution brought by Omet into the new millennium, together with flexo sleeve concept showed for the first time on Varyflex during the same exhibition.

Six years later, during Labelexpo 2007, OMET promoted a new “revolution” with the XFlex: it was the first press with short web path, thanks to the integration of the chill drum with the impression cylinder, allowing for the least start-up waste on a narrow-web flexo press. XFLEX was also the first machine featuring the Vision System able to achieve a perfect printing register, with no manual operations, simply by pressing a button. During the live demonstrations, the visitors looked for the “trick” that allowed to obtain a perfect register of 0,05 mm, independently from the skills of the operator.

The same “trick” was shown in every following exhibition, where OMET continued to bring further innovations, as a sign of constant investment in research and development: the first variable-size rotary die-cutting unit (MonoTwin Cut) and the first flexo-digital inkjet hybrid press (X-jet) in 2009; the first flexo-offset press with automatic sleeve format change (XFlex X6 Offset) in 2013; The first press with pre-registration through laser pointer and iVision system for real-time register adjustment (iFlex) in 2015.

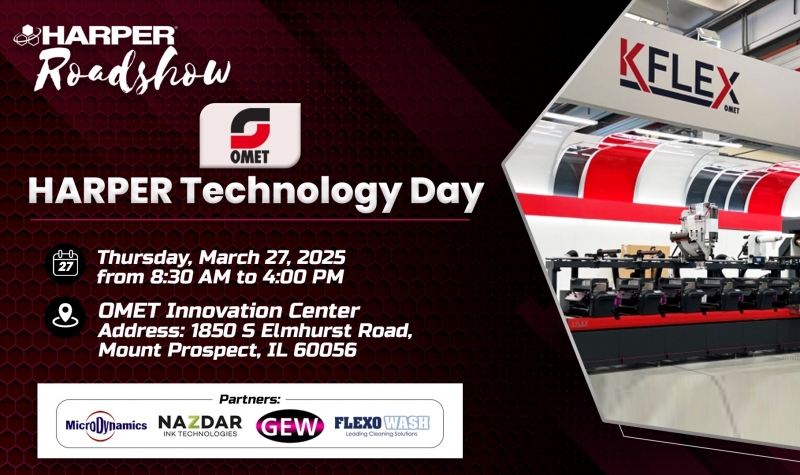

For the next edition of Labelexpo OMET will confirm its passion for innovation, showing 3 presses with new relevant technologies and developments: a little taste of the complete product portfolio. OMET is able to provide printing machines for any necessity, from the simplest label to complex applications, from combined printing technologies to special solutions and tailor-made projects.

You will find incredible innovations at OMET booth C49-C53 , hall 6.

Because this is what OMET does.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group