Helf Etiketten (Austria) invests in OMET Offset printing solution

With the installation of the OMET X6, Helf Etiketten has become the „Specialist“ in offset printing inside the Bizerba Group, German leader in labelling and weighing technologies.

The investments made in 2016 allowed Helf Etiketten to achieve ambitious goals. The Austrian company, with headquarter in Wiener Neudorf, which operates in the label sector, aimed at widening the productive capability to satisfy the growing demand on the regional market and developping specific know-how to standardize the production.

Joachim Zeiler, company CEO, explaines: „After being acquired by Bizerba Group in 2015, Helf Etiketten had a remarkable growth followed by relevant investment in equipment and facility“.

Entering the offset printing market

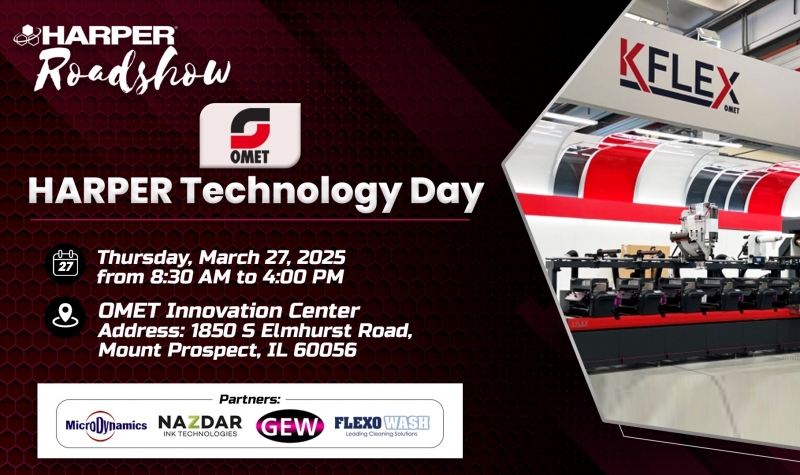

The installation of the OMET X6 had a great impact. The configuration of the machine, installed in august 2016, includes five offset printing units and three flexo printing units. Offset is the basic technology. Hannes Fink, Operations Director, aims: „Even if offset technology was a new entry for the company, start-up was simple and fast. Afetr less then one month from the delivery, we were ready to sell the products to the market“

In origin, Helf Etiketten worked in publishing and flexographic printing. Then, in 2007, the company invested in digital printing and started using the first HP Indigo system. The purchase of UV flexo machine, 530 mm wide, enabled the company to end the publishing business that was not profitable.

New printing process: a conscious decision

The purchase of a new hybrid offset+flexo solution with the OMET X6 was the result of an accurate evaluation. Hannes Fink explains: “Austria and South Germany are more oriented towords offset printing and the growth in the local market was one ofour main goals. We tought that offset technology was the right choice to be more competitive. We evaluated the top-rated press suppliers. The first requisite was the width: Helf Etiketten works on 530 mm width both on conventional process and on digital printing; as a consequence many suppliers were cut off from the competition; in the meanwhile one of the possible supplier went bankrupt“.

A convincing solution

The deciding factor was the presence of Chomos Gmbh as commercial parter in the German market. „The offer was very persuasive thanks to performance, printing quality and automation technology, together with customer service before, during and after sales“ explained Hannes Fink.

Beatrix Hochleitner of Chromos Gmbh, thanks to her long experience, knows well the importance of the planning when a printer has to start with a new process. For this reason, Chromos office in Augsburg organised for Helf several press demostration with OMET X6 operators in Lecco (OMET Headquarter).

An expert and reliable partner

Joachim Zeiler affirms: „The collaboration with Chromos was excellent. The foundations of a contract are made by technical and economic aspects. The advice and support provided by Chromos in all phases have been crucial. They were always ready to reply to questions; there was a specialised staff ready in every moment and all the agreement were respected. Nowadays it’s rare to find reliable partners like them“.

„Even OMET pays close attention to the quality. The press configuration is suitable with Helf specifics in terms of costs and benefits. Furthermore, the press is equipped with Plug-In®-Label system developed by Bizerba for smart control of prices and goods labeling”.

The quality makes orders grow

The majority of Helf clients are from Food and Retail market where printing quality and product standardization are extremely relevany, especially when printing long run jobs. Joachim Zeiler explains: “The decision of printing with offset technology was taken also to increase the orders and we have already achieved some results in this sense”.

In terms of quality, offset printing mainly satisfies clients that seek for sophisticated products with complex details and fine balance between colors. Letterpress printing couldn’t reach such results, whereas OMET X6 offset is able to satisfy orders where high quality is required. At the same time, even flexo printing jobs increased, given that they can be carried out more efficiently. Few months after the installation, the press was working in two shift and the output was over every prediction.

High paper application thanks to IML label

An essential advantage for Helf Etiketten is the wide know-how of Bizerba Group in IML label industry, a constantly growing segment. For this kind of products, Wiener Neudorf production site can take advantages of special adhesive material produced in Bizerba labelling plant in Bochum.

New press quickly under control.

Joachim Zeiler continues: “The introduction of new printing process was easy thanks to the support provided by OMET and Chromos. “The operators acquired self-confidence in managing the sophisticated press system very quickly”.

Currently the machine works at the average speed of 100m/min but Hannes Fink sees further optimizations by using the OMET X6 at its maximum speed of 200m/min. Helf expects to increase the press output by moving the die-cutting process off-line. GEW UV system has already been prepared to guarantee operations even at high speed. Low migration inks can be used at 100% on the press of Helf Etiketten.

Strengthen position in Austrian market

Founded in 1948 in Wiener Neudorf, near Vienna, Helf Etiketten Gmbh has 66 employees and a 12-million-euro turnover (2016). Nine orders out of ten comes from Austria, the rest from Germany and Switzerland. In 2015, Bizerba Group took over the majority of the company. The well-known group, leader supplier in weighing technology and labelling systems, with headquarter in Balingen, counts on many plants with more than 100 million turnover in labelling sector. The Helf Etiketten acquisition reinforced his position in the Austrian market.

Thanks to Klemenz Ehrlitzer and Chromos Gmbh for allowing the pubblication.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group