Aussie First For Label Power Queensland with OMET KFlex 530

Trade shows often provide the impetus for strategic investment, and a visit to Labelexpo Europe last year inspired Label Power founder and CEO, James Malone, to invest in the country’s first OMET KFlex 530 narrow-web flexo press from Currie Group.

Label Power, which has production facilities in Sydney, Melbourne and Brisbane, specialises in custom label printing, barcode solutions and associated tools, for a wide range of customers across the country.

With a fleet of flexo and digital presses, it provides a complete solution for small businesses, manufacturers, retailers, logistics, healthcare providers, food and beverage, and more. While much of this work is short and medium runs, the company was also looking to expand its capacity for longer-run, high-volume jobs, leading to this latest search.

After attending the Brussels trade show, James says Label Power’s management and technical team conducted further research on the available options, including a visit to OMET in Lecco, Italy, for one-on-one demonstrations of the revolutionary new technology.

“The demonstrations of the new OMET KFlex 530 were very impressive and, after further discussions with the team at Currie Group, we were soon convinced that it would be the perfect strategic investment to support our existing press line-up and allow us to diversify further in future,” James recalls.

“Prior to this, we have had more typical, narrow-web flexo machines with 250mm, 330mm and 430mm widths. The new OMET KFlex 530, with its 530mm web width, takes us into new territory, allowing us not only to produce larger label sizes, but also to increase volumes further by fitting an extra row or two of labels onto the web,” he says.

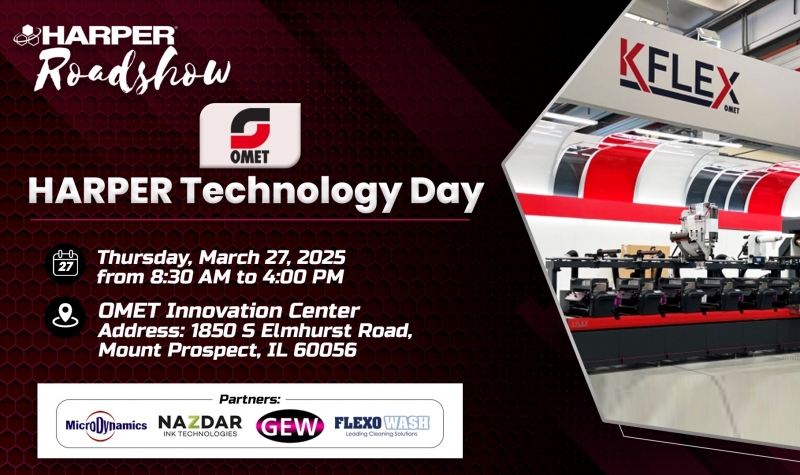

Installed last year, the new press features OMET’s SWITCH system, which allows the adaptation of the press configuration for the requirements of each job. Further flexibility is delivered with options including modules for energy-efficient GEW water-cooled UV LED curing, delamination and relamination, and die cutting stations.

“Importantly, this productivity and flexibility doesn’t come at the cost of quality,” James adds. “Our customers require the highest standards, always, and the KFlex, with its automated registration, precision print and options like GEW low-energy UV curing, enables us to meet even the most exacting requirements, while keeping a lid on costs.”

Label Power’s long -term partnership with Currie Group, which has included the purchase of other equipment like our HP Indigo digital label presses, was also an important factor in the decision.

“We know from experience that they have the support on the ground, and we can rely on their strong technical expertise and factory-trained engineers for any support we need.

“All in all, it’s proven to be a great investment, allowing us to accept even the most challenging high-volume work with confidence.”

With thanks to Label Plus and Currie Group

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group