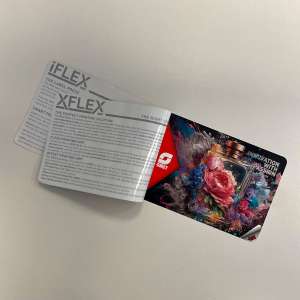

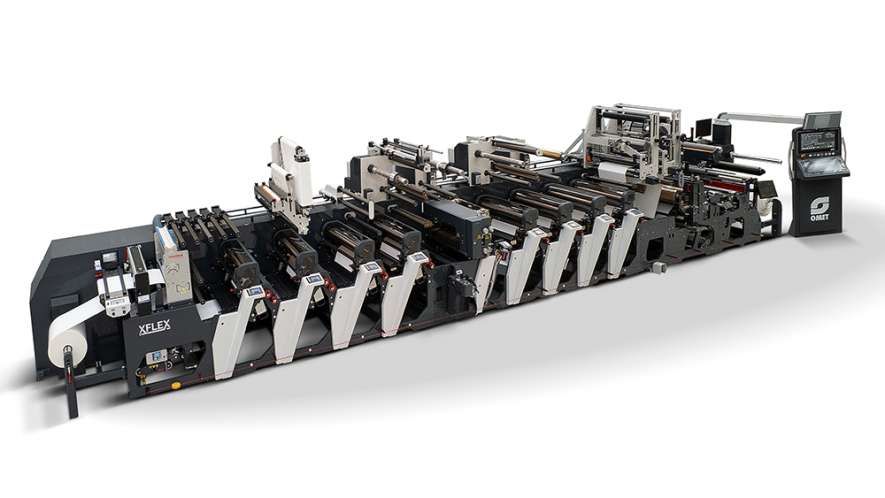

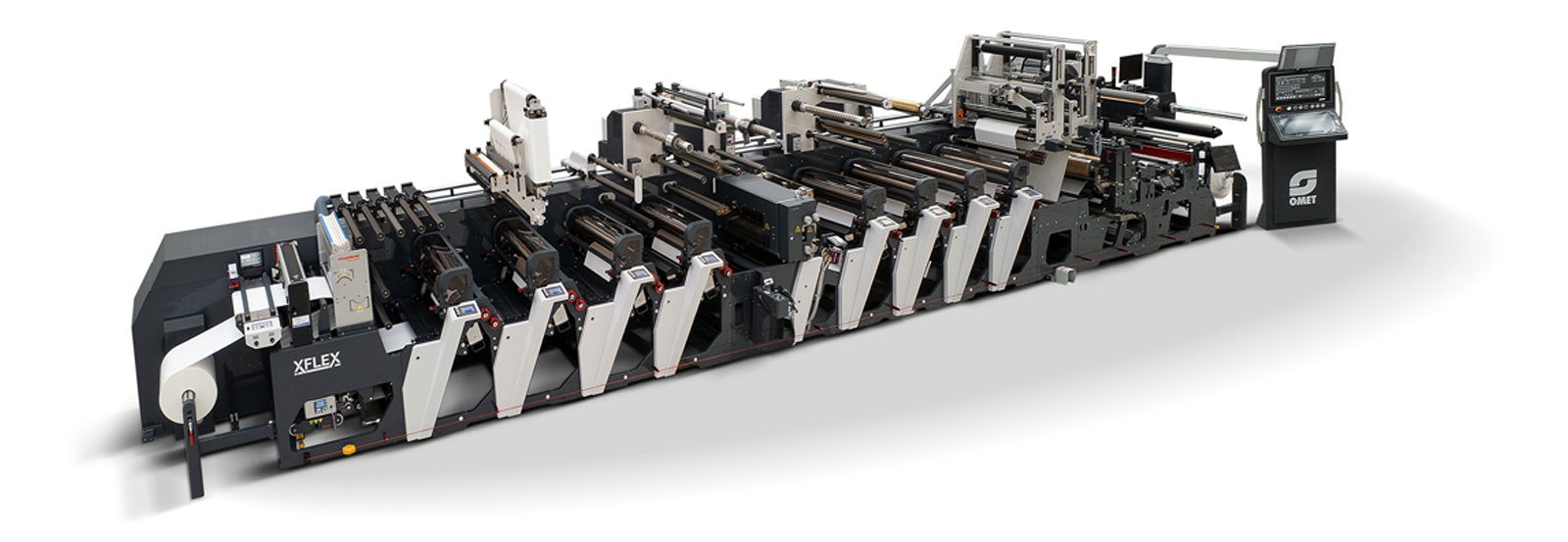

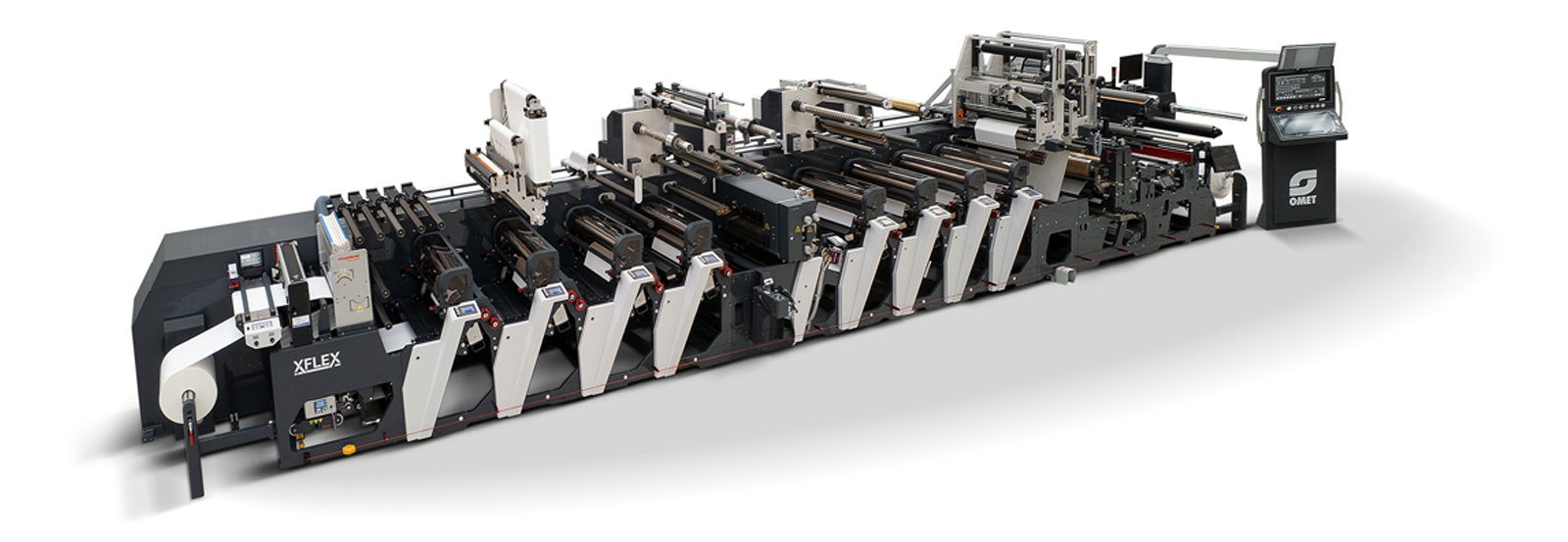

The new XFlex X6.0 is the natural evolution of the renowned OMET XFlex X6 printing line, the real step towards digital workflow and independent process. It is going to set higher standards in performance and quiality by preserving the strong points that made XFlex X6 the best narrow-web platform on the market and integrating them with state-of-the-art technologies and automation.

A complete restyling and a modern interface with touchpad controls make the press even more user-friendly, ergonomic and intuitive, offering the operator a new working experience and the comfort of a fully automatic and independent process. The XFlex X6.0 enhances the potentiality of flexo printing and provides printers with the opportunity to improve their production potential and extend their product portfolio with top-quality results and sure return of investment.

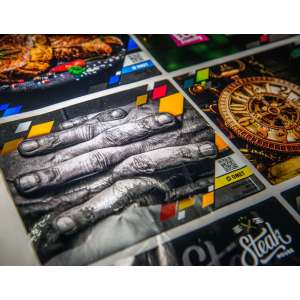

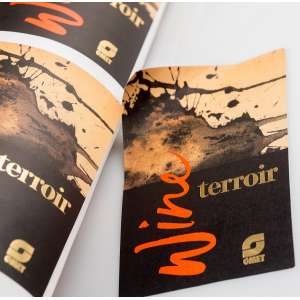

The Xflex X6.0 flexo press is a pay-back investment for any company looking for high productivity, efficiency and astonishing printing results. It is able to integrate several printing and converting technologies in-line and process all kind of substrates, from 12-micron film to light carton, producing many types of applications to satisfy the requests of different target markets.

All press operations and the whole machine ergonomics have been designed to facilitate the printers’ work. XFlex X6.0 offers maximum reliability and safety, promoting rapid and effortless handling.

Flexo Direct-Drive technology and gearless concept eliminate even the smallest imperfection and allow the press to reach the purest quality with no backlash and perfect register stability, even at the highest production speeds.

The modular design allows to combined and implement in-line, with no limitations, different printing technologies, as well as special finishing applications and converting units, to always get to the final product in one single passage.

The integration of Digital Servo Drives enables very accurate set-up operations and automatic on-the-fly pre-registration of the plates to get them in position simply by pressing a button, with no waste of time and material.

Multivision: Color-to-Color automatic register adjustment based on a multiple camera scanning system. It can control both machine and cross side of each single printing unit in real time and get the machine ready to print in less than 1 minute, generating nearly no waste.

| 340 | 430 | 530 | |

|---|---|---|---|

| Max speed | 200 m/min | up to 200 m/min (690 fpm) | up to 200 m/min (690 fpm) |

| Unwinding reel diameter | 1000 mm (40'') | 1000 mm (40'') | 1000 mm (40'') |

| Web width | 340 mm (13 3/8'') | 430 mm (16 7/8'') | 530 mm (20 7/8'') |

| Print width | 330 mm (13'') | 420 mm (16,5'') | 520 mm (20,45'') |

| Infeed/Outfeed | servo driven | servo driven | servo driven |

| Printing axes | indipendent direct driven motor, gearless technology | indipendent direct driven motor, gearless technology | indipendent direct driven motor, gearless technology |

| Cross registration | Automatic | Automatic | Automatic |

| Longitudinal regulation of print | 360° | 360° | 360° |

| Printing plates technology | Plates mounted on sleeves | Plates mounted on sleeves | Plates mounted on sleeves |

| Automatic register control | Automatic | Automatic | Automatic |

| Quick Ink Change System | Quick change | Quick change | Quick change |

| AVAILABLE PRINTING TECHNOLOGIES | |||

| Flexo UV/UV LED | 12'' - 25'' | 12'' - 25'' | 12'' - 25'' |

| Flexo Water Base | 12'' - 25'' | 12'' - 25'' | 12'' - 25'' |

| Offset (Sleeve) | 14'' - 25'' | 14'' - 25'' | |

| Rotary silk-screen | 12''- 25'' | 12''- 25'' | 16''- 25'' |

| Rotogravure | 12'' - 26'' | 12'' - 26'' | |

| CONVERTING | |||

| Double die-cutting station | 12''- 25'' | 12''- 25'' | |

| TWIST die-cutting unit | 12''- 25'' | 16''- 25'' | |

| Monotwin Cut | 12"-20" | 12"-20" | |

| Rock’n’Roll "Dual Funtion" matrix stripping | 760 mm (30”) | 760 mm (30”) | 760 mm (30”) |