OMET to disrupt shrink sleeve printing with the new X7

OMET, the leader in pathbreaking technology and solutions for the flexo and combination printing presses, at LabelExpo Europe 2019 will launch a new printing press: XFLEX X7, which is set to disrupt the shrink sleeve and flexible packaging printing market. This 670mm (26”) flexo printing press comes with a suite of innovative features and will showcase for the first time a new (HVR) Print Unit.

In today’s competitive world, brands are continuously asking leading printers of the world to present innovative solutions which could help them attract customers at point of sale for a better conversion. When product differentiation becomes negligible, packaging plays a very important role in creating the premium perception in the mind of the customer. It is for such reason, the new trend in the market is to add a premium look and feel to shrink sleeves and flexible packaging using specialized varnish which creates special effects on these materials.

Sensing this need of the printers and their customers for applying varnishes for special effects, tactile features such as soft touch, leather, sand , textiles, peach, etc… on shrink sleeves and flexible packaging, OMET launches its new modular printing and converting platform, XFLEX X7.

This 670mm (26”) printing press merges best features of OMET’s earlier top selling platforms of XFLEX X6.0 and VARYFLEX V2 into a new innovative printing press. It now gives printers the possibility to offer high quality, high value shrink sleeves and flexible packaging materials optimized to print for medium volume quantities, which now has become the trending order size of leading brand owners.

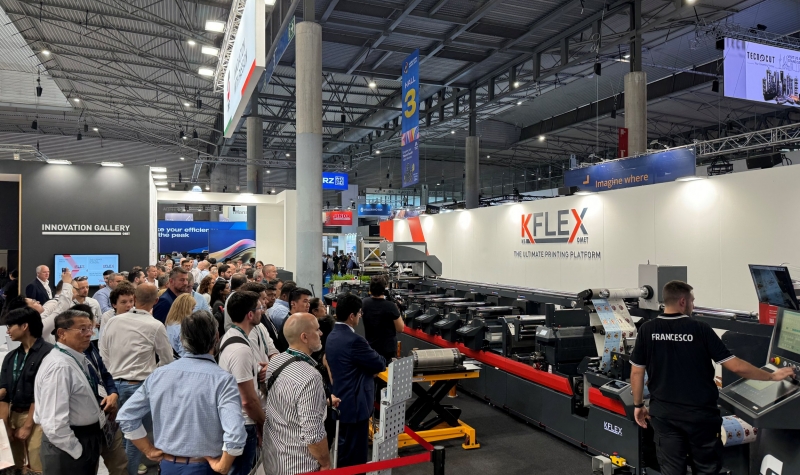

OMET has industry’s largest range of modules and attachments and with the new X7 we present our latest offering, the High Value Rotogravure-HVR, which we believe will disrupt the way printers achieve the special print effects on shrink sleeves and flexible packaging materials” said Amerigo Manzini, Director R&D at OMET. “HVR will be on display at Labelexpo Brussles at our stand in Hall 6, C49-53 and we encourage all innovative printers of the world to come and experience it running live! Also available will be various samples printed with HVR allowing printers to see the new possibilities they can now achieve with much east with this innovation” added Manzini.

In addition to the HVR, X7 also integrates several printing and converting technologies in-line along with a new flexo station designed with Zero Gears Solution which allows maximum level of precision on the market. It has 9 Servos on each printing unit offering fully automatic printing pressures, automatic on the fly pre-registration and the OMET’s patented MULTIVISION registration camera allowing the machine to have the fastest setup times with the near zero wastages.

X7’s modular design also allows OMET to offer different possibilities of combination printing and special effects with the Soft Touch Vertical Flexo Station and a new rotary screen unit available in 670mm. “Our Soft Touch Vertical Flexo Station is another great unit to be seen at the show, as it allows printers to work with soft touch applications with both water and solvent based inks” Manzini Stated while speaking about the versatility of the X7.

With the capability to print from 12microns and a variety of other substrates, the X7 will be a “Not to be missed” highlight of Labelexpo Brussels which will give a new dimension to shrink sleeve and flexible packaging printers in providing next generation solutions to their customers!

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group