OMET leaps ahead in hybrid printing with the new OMET XJet powered by Durst

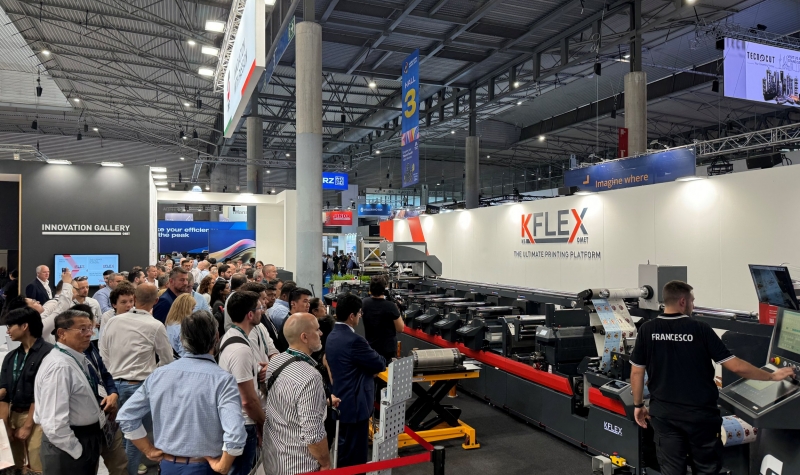

Now offering faster speeds, wider width and higher print quality in a more compact, user-friendly and integrated solution with fully automatic register and control. For Printers looking for significant competitive advantage with hybrid technology, the new model of OMET XJET, is on the top compared to existing hybrid systems, as demonstrated by OMET during the recently concluded Labelexpo Brussels.

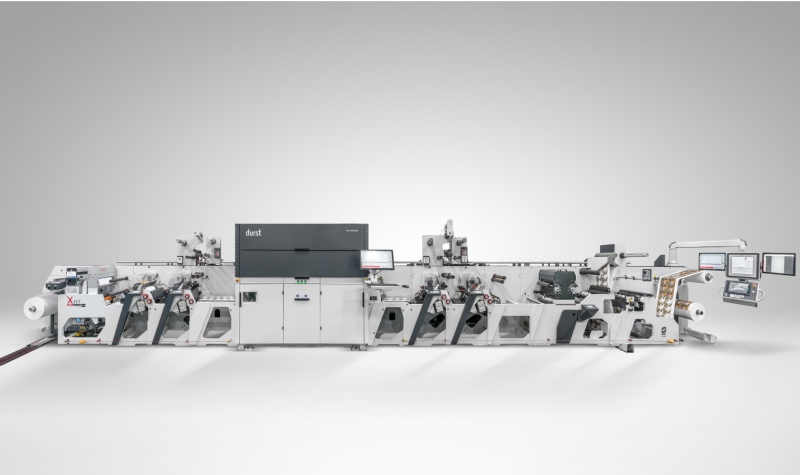

OMET XJet printing press is the extraordinary result of the combination between the renowned OMET flexo quality and DURST digital inkjet printing technology, plus exclusive finishing and converting units to obtain the final product always in one single pass. This partnership has made possible, the perfect hybrid solution able to provide the maximum level of productivity, independent from the length of the run.

On the XJet, printers enjoy the benefits of digital technology, such as – immediacy, variable data, personalization and high uptime, along with new high performance features such as in-line integration of finishing units (cold foil, hot foil, silk screen, varnish …) and converting units (multi-layer, die-cutting, slitting..). Additionally, OMET flexo stations enable primers and special varnishes application, pantone or metallized color printing, compensating for the limitations of today’s digital technology. Printers can choose the most convenient combination of technologies at every run, adapting the production to changeable market trends like personalization, just-in-time deliveries and final product valorization.

Latest developments implemented on the OMET XJet include faster speed (80 m/min up to 100 m/min), wider solutions (330 – 420 – 510 mm digital printing width), and the automatic nozzle compensation system, ensuring the best quality today available on the market in day-to-day production.

OMET hybrid platforms are now capable of producing shrink label printing and many other special applications along with the printing of every kind of self-adhesive labels.

“We are working on further developments aiming at expanding the range of final applications – says Marco Calcagni – to satisfy the demands of our globally respected customers who themselves are pioneers in innovations. The XJet is requested by label companies that see benefits in a total hybrid solution, being able to provide an extended range of new opportunities and widening significantly their product portfolio. We also see significant interest coming from digital printers who want to optimize their production process: printing, finishing and converting in-line with focus on single pass production, by using only one machine instead of 2 or 3 being used currently. We expect 2020 being the year of “the Pivot of hybrid” and faster growth of installations in 2021”.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group