Exploring the Flexo Wash and OMET Partnership: Enhancing Printing Efficiency

In the world of flexographic printing, partnerships often hold the key to refining printing processes. One of these collaborations is the partnership between Flexo Wash and OMET.

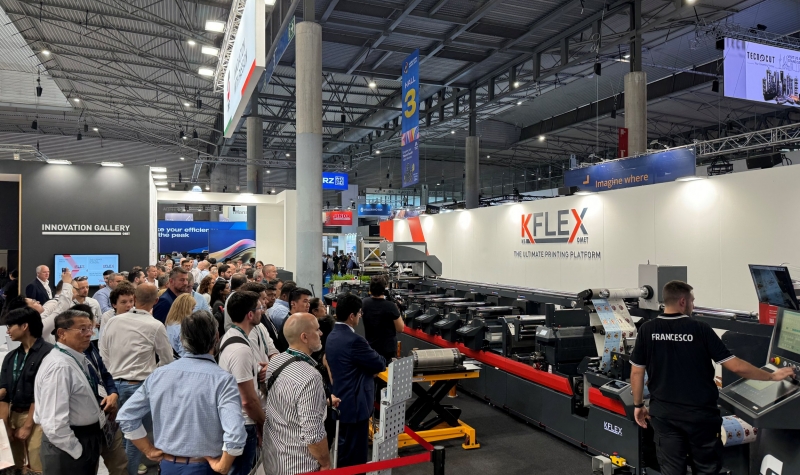

As a provider of cleaning solutions for the printing industry, Flexo Wash has taken a significant step by establishing a showroom within OMET’s Innovation Park. This partnership highlights Flexo Wash’s commitment to customer service and emphasizes the important role that industry collaborations play in elevating customer experiences.

Flexo Wash has gained recognition for its innovative cleaning machin es and solutions that revolutionize the efficiency and quality of the printing process. OMET is recognized for its quality in manufacturing printing presses and converting machinery. Together, Flexo Wash and OMET have created an immersive environment for customers, offering them the opportunity to gain insights into how the seamless integration of Flexo Wash’s cleaning solutions with OMET’s printing presses can elevate their printing operations.

es and solutions that revolutionize the efficiency and quality of the printing process. OMET is recognized for its quality in manufacturing printing presses and converting machinery. Together, Flexo Wash and OMET have created an immersive environment for customers, offering them the opportunity to gain insights into how the seamless integration of Flexo Wash’s cleaning solutions with OMET’s printing presses can elevate their printing operations.

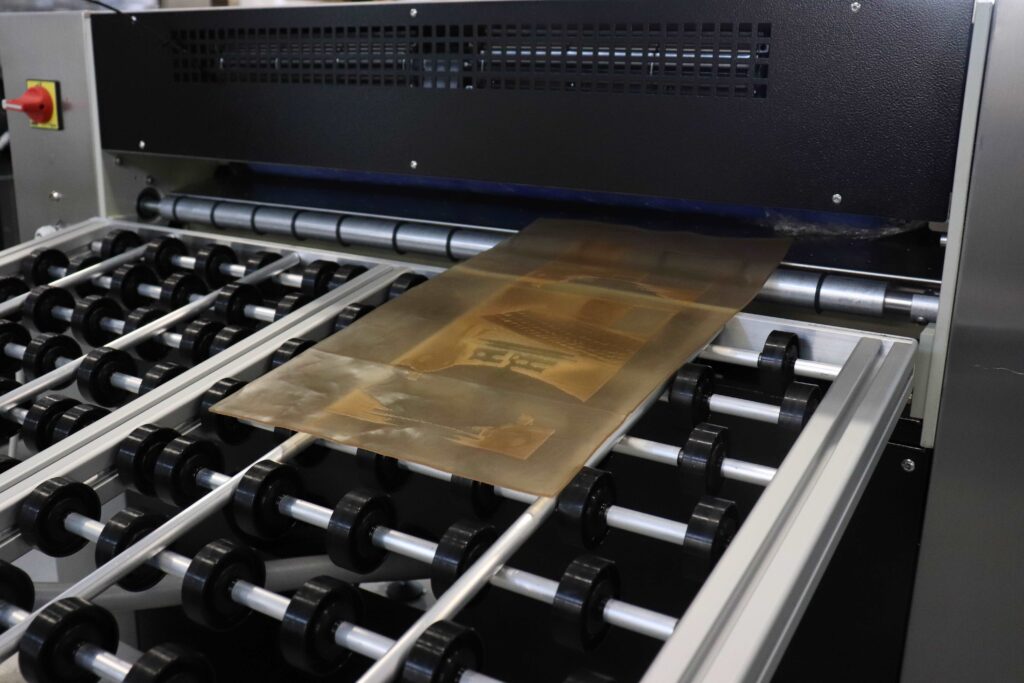

The showroom at OMET serves as a platform for customers to board on an informative journey through Flexo Wash’s diverse range of cleaning machines, including plate washers, part washers, and anilox roll cleaners. The primary intent is to provide customers with a practical and insightful experience, empowering them to optimize their printing processes effectively. Customers can explore the equipment and gather valuable information about its features and capabilities.

The partnership between Flexo Wash and OMET Innovation Park has the customer as the core focus. By providing a dedicated showroom where customers can immerse themselves in the seamless integration of cleaning solutions with printing presses, both companies offer a valuable service to the flexographic printing industry.

Five reasons why you should visit the Flexo Wash showroom at OMET Innovation Park:

Hands-On Evaluation: A visit to the Flexo Wash showroom allows customers to get up close and personal with the cleaning machines. They can touch, feel, and interact with the equipment, gaining a firsthand understanding of its build quality, user-friendliness, and ergonomic design.

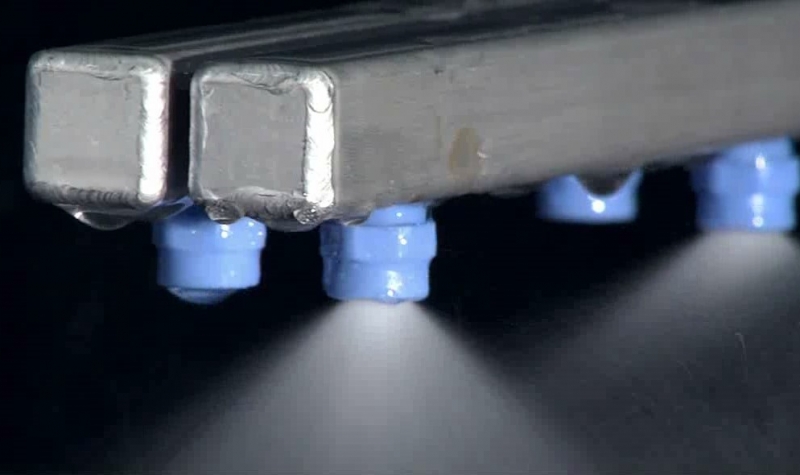

Operational Efficiency Assessment: While the machines may not be running, customers can still assess their operational efficiency by examining the equipment and discussing its features. They can observe how the machines are designed to effectively remove ink and contaminants, gaining insights into how it can enhance their production processes.

Customization Considerations: During their visit, customers can explore the equipment’s features and capabilities, allowing them to consider how it can be customized to meet their specific needs, even if they can’t discuss customization directly with experts.

Cost-Efficiency Assessment: By observing the cleaning machines and gathering information about their features, customers can evaluate their potential cost-efficiency. They can consider factors such as energy consumption, consumables usage, and maintenance requirements, helping them make more informed cost estimates and evaluate the long-term return on investment. The cost-efficient solutions considerably increase printing press capabilities. This leads to streamlining of processes, resulting in quicker setup times, consistent print startup, and improved print quality. Moreover, more efficient troubleshooting contributes to overall operational efficiency, therefore highlighting the importance of embracing cost-efficient solutions in the printing industry.

Optimize Your Workflow: If your current washing area is slowing down production, rely on Flexo Wash cleaning solutions to help you achieve a more streamlined workflow. Say goodbye to hurdles for your team and welcome smoother operations.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group