OMET KFlex K6 Makes Its World Debut at Labelexpo Europe 2025

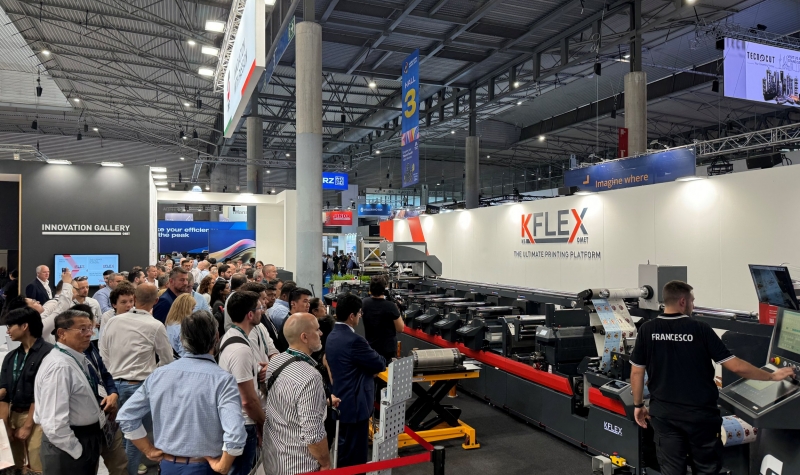

Labelexpo Europe 2025 took place in Barcelona from September 16 to 19, with the new OMET KFlex K6 as one of the main highlights. The machine drew strong attention from market operators thanks to its many innovations, designed to simplify operators’ work while ensuring top-level printing quality.

The new OMET KFlex K6 made its world debut at Labelexpo Europe 2025 in Barcelona, immediately drawing strong interest from converters, brand owners, and industry professionals. Visitors gathered to discover the machine’s innovations, which combine advanced automation, modular design, and new technologies, positioning the K6 as a key reference point for the future of flexo printing.

At the heart of the K6 lies a completely re-engineered flexo unit, designed with a gearless direct-drive transmission optimized for sleeve technology which provides maximum stability and printing precision. Operators immediately appreciated the ease of use brought by the AutoMate Technology featuring wide touch panel HMI on every unit, smart multicolor LED indicators, and automated hands-free guard opening. Plus, the automatic printing pressure adjustment reduce human intervention to a minimum, lowering operator stress and potential errors while consistently delivering higher print quality.

Cold Foil Saver: Eco-Efficiency in Action

Another highlight of the K6 is the redesigned Cold Foil Saver, capable of managing up to four foil lanes with two reels with independent and simplified adjustment for each lane. This innovation not only boosts flexibility but also doubles productivity using the same amount of foil. By drastically reducing waste, the system stands out as an environmentally responsible solution that delivers immediate cost savings to converters.

ECDC: The Next Generation of Die-Cutting

The K6 also premiered an improved version of the Easy Change Die-Cut (ECDC) system, which impressed visitors with its speed and safety. The changeover of the magnetic cylinder can be completed in under a minute, requiring minimal effort. Automatic pressure positioning eliminates the need for manual intervention, while on-the-fly pre-register adjustment ensures uninterrupted production. The system incorporates the new OMET Gap Pro, an in-house development for micrometric depth adjustment, designed and produced internally, with no third parties involved. The result is a faster, safer and more precise die-cutting set-up and process, setting new standards for efficiency and operator convenience.

Multivision+: Smarter Register Adjustment

Precision and waste reduction take a giant leap forward with the new Multivision+ register adjustment system with multiple smart cameras on each unit for real-time register fine-tuning with the maximum accuracy. Thanks to a new dedicated reading pattern and the exclusive MCM technology, the waste on the edges of the web is limited to 6 mm for the entire run, regardless of the number of colors. It can control up to 17 units, including the die-cutting lateral and longitudinal register. This system delivers up to 80% reductions in waste and setup time, while offering absolute repeatability and a fully automated workflow.

SWITCH Interchangeability: Maximum Flexibility

One of the strongest assets of the K6 is the ability to interchange different printing and converting units on the same platform thanks to the SWITCH system. This exclusive feature provides extreme flexibility, ensuring fast production adaptability and the capability to quickly respond to market demands. At Labelexpo, OMET introduced a brand-new cassette-style offset unit featuring sleeve technology, which can be extracted for maintenance operations and interchanged in different positions. The new Offset unit is the first and only solution featuring SWITCH system, Easy Sleeve Format Change, Improved dampening calibration with 4 form rollers in contact with the plate and Improved ink grinding.

A New Benchmark for the Industry

The world premiere of the KFlex K6 demonstrated not only OMET’s technical excellence but also its clear vision for the future of printing. By combining eco-efficiency, operator-friendly automation, and modular versatility, the K6 is set to redefine productivity and quality standards for label and packaging converters worldwide. Judging from the enthusiasm at Labelexpo Europe 2025, the industry is more than ready to embrace this new era of printing.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group