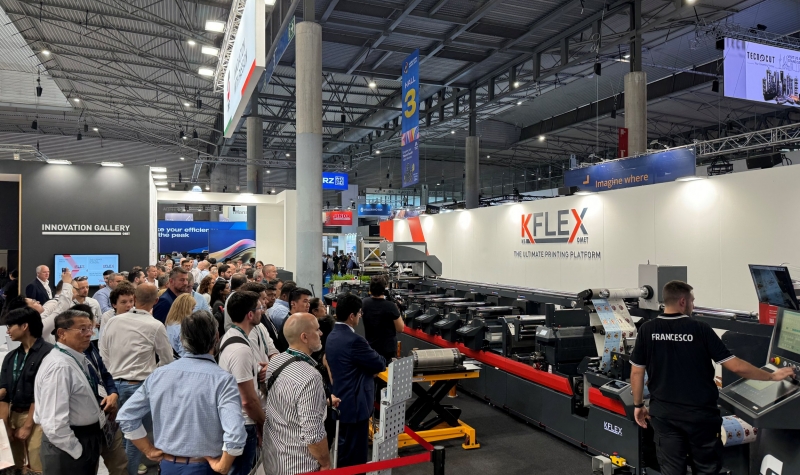

OMET KFlex: total flexibility at the printer’s disposal

On June 24th, 2022, OMET officially launched its new narrow-web machine for labels and flexible packaging: the KFlex. This new fully servo-driven model with a web path of 430mm or 530mm and maximum printing speed of 200 m/min, comes from listening to the customers’ needs. The KFlex was entirely designed for the operator to offer the maximum ease of use and intuitiveness; in fact, this press combines unprecedented flexibility and cutting-edge technology to offer high performance at low production costs.

The strength of the new KFlex is its unprecedented modularity that makes it a multitasking platform able of integrating different printing and converting technologies in line, and processing all types of substrates, from 12-micron film to lightweight cardboard, with different applications ranging from self-adhesive labels to shrink sleeve, from aluminum labels to lamitube. This, to meet the demand of different targets: wine & spirits, food & beverage, healthcare and many other markets.

The machine is designed to be intuitive and safe for printers to use, to improve set-up times and reduce material waste. The new Dual Servo standalone flexo cassette can be configured with UV drying on chill drum, UV on the web, or hot air, and a modern interface with touchpad controls make it easy to use as it integrates all the main operating functions, preventing the operator from constantly moving between the end and beginning of the line. Reduced paper passage significantly limits the level of material waste, and the integration of next-generation servo motors allows automatic adjustment and control of register, as well as double pass and slipping operations.

The flexibility of this machine also allows the integration of special paper passes for applications of UV varnishes, high opacity water-based varnishes and inks, or special Soft Touch coatings, as well as the unique ability to reverse print without the use of flip bars.

The flagship of the new KFlex is the revolutionary SWITCH system that allows interchangeability between printing and converting units through quick and easy operations. The ability to replace a flexo cassette with a removable die-cut, an ECDC unit, a hot foil, a screen printing unit or a digital print bar, goes in the direction of ensuring the flexibility of the printing process and allows for quick reaction to production needs, even if only temporary, required by the market or a particular job. With this system, OMET wants to introduce the concept of Business Continuity, which allows the printer not only to have a highly adaptable and unique platform, but also to limit downtime due to unforeseen technical issues.

Equally simple and versatile is the die-cut with Easy-Change technology, which allows the magnetic cylinder to be replaced quickly and effortlessly, without the need for any lifting device. Thanks to its sliding system, all tools can be prepared offline and then easily inserted into the die-cutting station, safely and effortlessly.

Designed for a secure return on investment, the KFlex delivers high-quality print results coupled with the reliability of OMET’s advanced technology and expertise through user-friendly automation systems that implemented to simplify the operator’s life and decrease makeready time. The KFlex offers unrivaled print quality and register stability thanks to its Dual Servo flexo units that can automatically perform on-the-fly pre-registration, which avoids wasteful time and material regardless of the paper pass. This is combined with the unique register adjustment and control system, Vision, which automatically adjusts and controls the lateral and longitudinal register of each printing unit in real time without operator intervention, thus limiting start-up time and waste.

In addition, the operator panel displays images from 6 check & control cameras, that the customer can decide to place on critical points to better control the production process.

The modular design of the KFlex allows the combination of different printing technologies in-line with the maximum flexibility, as well as the addition of numerous special finishing applications and converting units, so that the final product is always obtained in one step. For example: cold foil, hot foil, peel&seal, delam-relam, embossing and varnishing. These optional units have been designed and redesigned to ease the operator’s handling and consequently reduce setup times.

The KFlex is the most versatile and easy-to-use solution for tackling highly diverse, ever changing and increasingly competitive markets. It’s the key to your success.

is the web magazine with all news about OMET Group

is the web magazine with all news about OMET Group