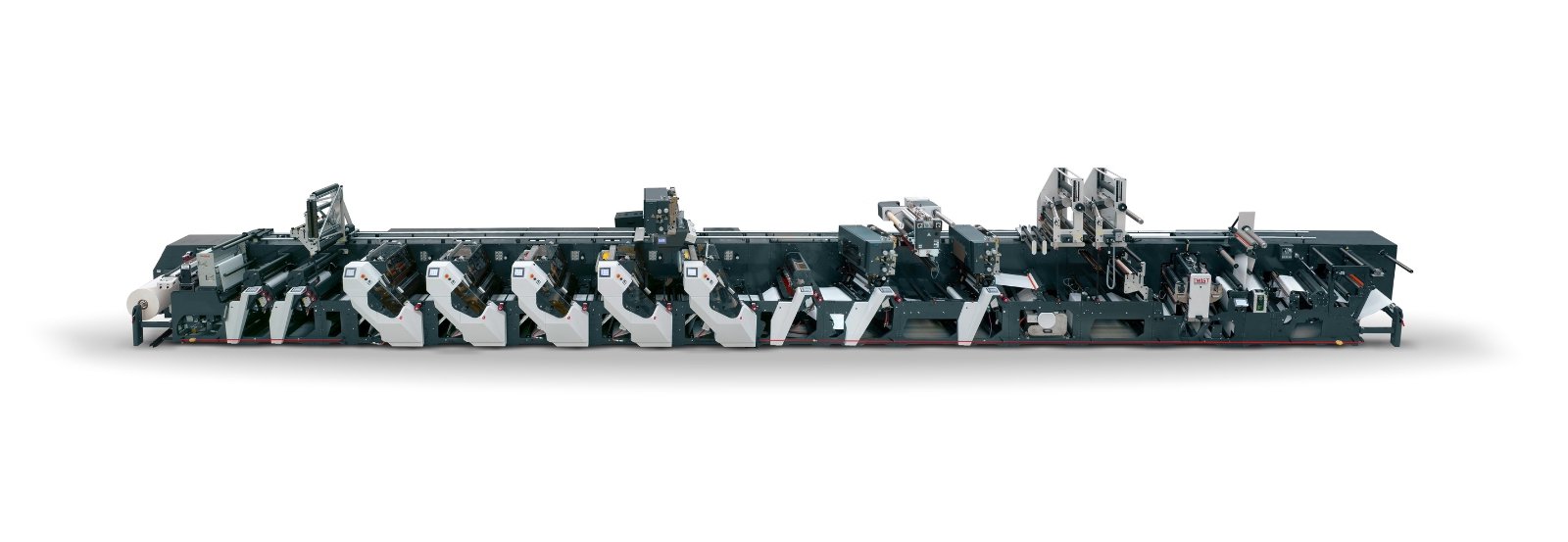

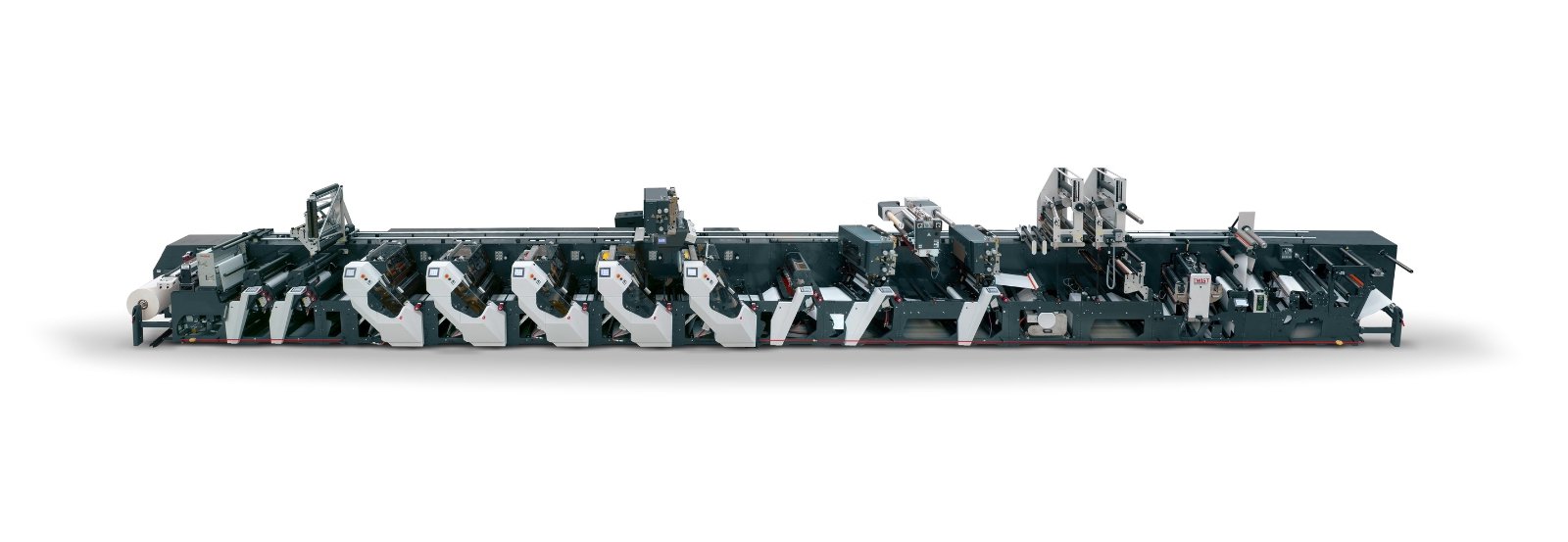

The modular design allows to combined and implement in-line, with no limitations, different printing technologies, as well as special finishing applications and converting units, to always get to the final product in one single passage.

| 430 | 530 | |

|---|---|---|

| Max speed | up to 200 m/min (690 fpm) | up to 200 m/min (690 fpm) |

| Unwinding reel diameter | 1000 mm (40'') | 1000 mm (40'') |

| Web width | 430 mm (16 7/8'') | 530 mm (20 7/8'') |

| Print width | 420 mm (16,5'') | 520 mm (20 4/8'') |

| Infeed/Outfeed | servo-driven | servo-driven |

| Printing axes | indipendent direct driven motor, gearless technology | indipendent direct driven motor, gearless technology |

| Cross registration | Automatic | Automatic |

| Longitudinal regulation of print | 360° | 360° |

| Automatic register control | Automatic | Automatic |

| AVAILABLE PRINTING TECHNOLOGIES | ||

| Offset (Sleeve) | 14''-25'' | 14''-25'' |

| Flexo UV/UV LED | 12'' - 25'' | 12'' - 25'' |

| Flexo Water Base | 12'' - 25'' | 12'' - 25'' |

| Rotary silk-screen | 12'' - 18'' | 12'' - 18'' |

| CONVERTING | ||

| Die-cutting section | Max 25'' | Max 25'' |

| TWIST die-cutting unit | Max 25'' | Max 25'' |

| Rock’n’Roll "Dual Funtion" matrix stripping | 760 mm (30”) | 760 mm (30”) |